Industrial IoT

Industrial Internet of Things (IIoT), often referred to as Industrial IoT, is a subset of the broader Internet of Things (IoT) concept that focuses on the application of IoT technologies and principles in industrial settings. It involves the use of connected devices, sensors, and data analytics to enhance and optimise various industrial processes.

Here are some key aspects of Industrial IoT:

- Connected Devices and Sensors: IIoT involves the deployment of a wide range of sensors and devices in industrial environments. These devices can collect data on various parameters such as temperature, pressure, humidity, machine status, and more.

- Data Collection: The data collected by IIoT devices is transmitted to a central system or cloud platform for processing and analysis. This data can be real-time or historical and is used to gain insights into industrial operations.

- Data Analytics: IIoT leverages advanced data analytics and machine learning techniques to extract valuable insights from the collected data. This can include predictive maintenance, quality control, and process optimisation.

- Remote Monitoring and Control: IIoT enables remote monitoring and control of industrial processes and equipment. This can lead to improved efficiency, reduced downtime, and cost savings.

- Predictive Maintenance: One of the significant benefits of IIoT is predictive maintenance. By analysing equipment data, it’s possible to predict when machines are likely to fail and schedule maintenance proactively, reducing unplanned downtime.

- Supply Chain Optimisation: IIoT can be used to track the movement of goods and materials within a supply chain. This enables better inventory management, improved logistics, and reduced wastage.

- Energy Management: IIoT can help organisations optimise energy consumption by monitoring and controlling energy usage in real-time.

- Safety and Security: IIoT can enhance workplace safety by monitoring environmental conditions and detecting safety hazards. It can also improve security by monitoring access to critical areas and assets.

- Scalability: IIoT solutions can scale to accommodate the needs of various industries, from manufacturing and energy to agriculture and healthcare.

- Interoperability: Ensuring that different IIoT devices and systems can communicate and work together is essential. Standardisation efforts such as OPC UA (Unified Architecture) and MQTT (Message Queuing Telemetry Transport) aim to address this issue.

- Data Privacy and Security: As with any IoT application, data privacy and security are critical concerns in IIoT. Protecting sensitive industrial data from cyber threats is a top priority.

- Regulatory Compliance: Depending on the industry and location, there may be specific regulations and standards that govern the use of IIoT technology. Companies must ensure compliance with these requirements.

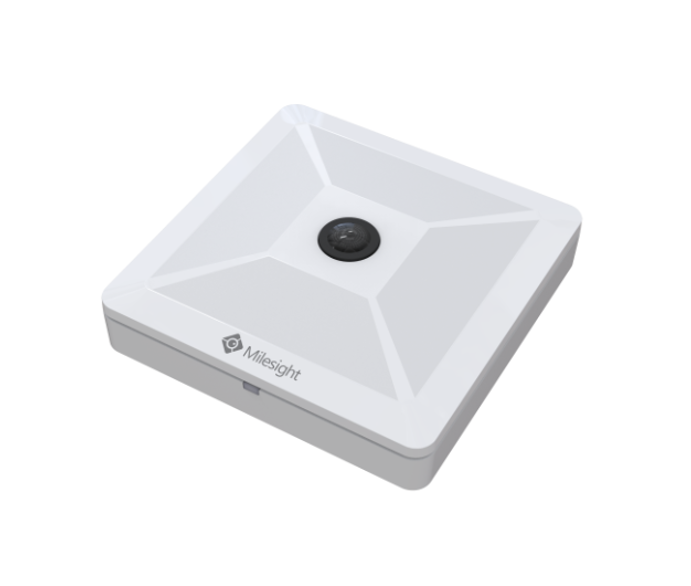

Our Solution is InGateway502 for the Industrial Sector

The InGateway502 is a new-generation edge gateway designed for industrial IoT.

With easy configuration – Uninterrupted and Highly Reliable Connectivity.

Purposely Designed for Industrial Scenarios

The IG502 features industrial-grade design. EMC level 3, IP30 protection rating, and wide temperature and voltage ranges make it enduring in challenging environments.

Conclusion

In summary, Industrial IoT (IIoT) is revolutionising industrial processes by leveraging the power of connected devices, data analytics, and automation to improve efficiency, productivity, and safety in various industrial sectors. It is an evolving field with significant potential for innovation and optimisation in manufacturing, logistics, energy, and many other domains.